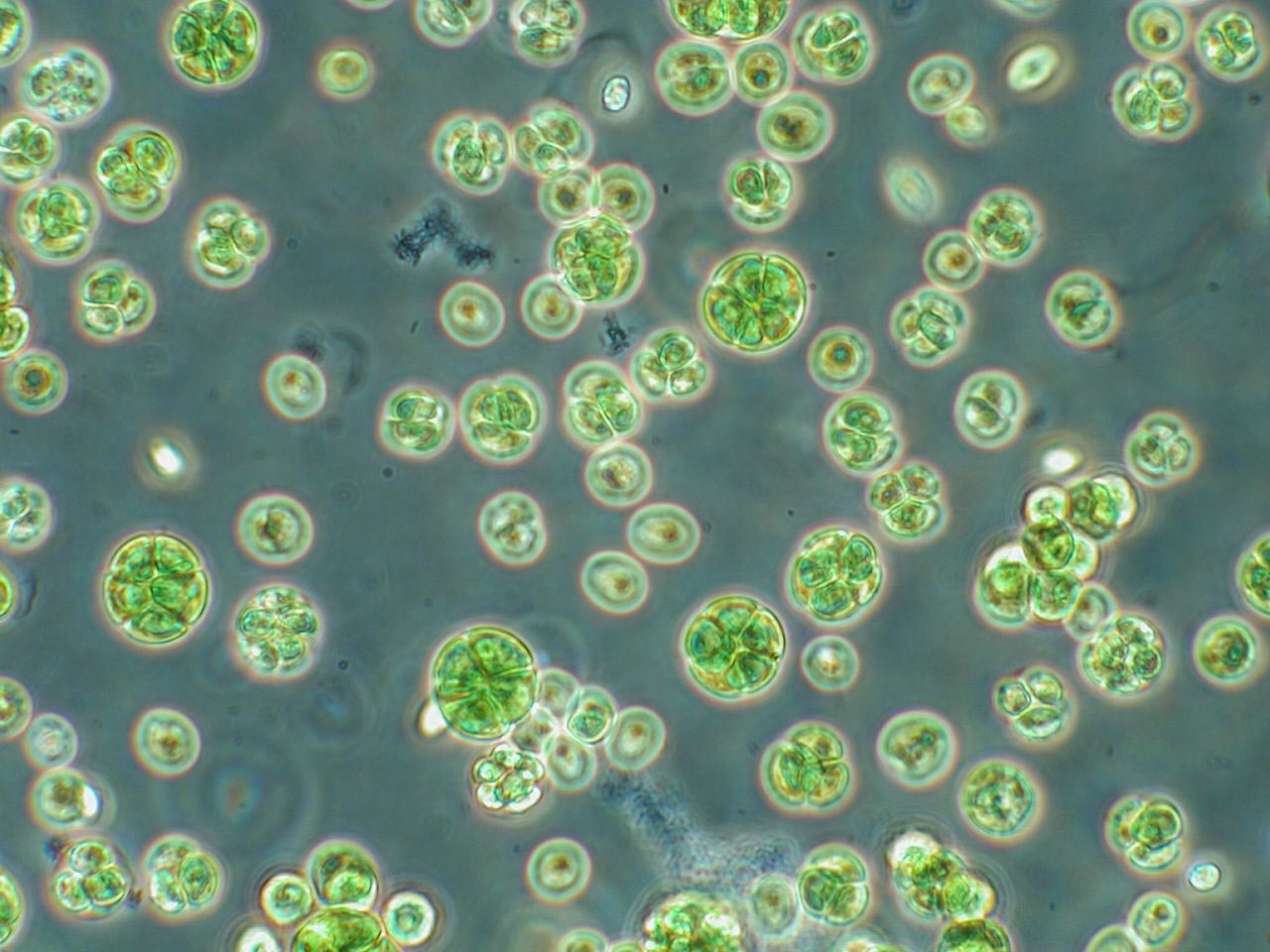

Microalgae

Microalgae are microscopically small unicellular organisms that grow up to 10 times faster than terrestrial plants. They live in sea- or in freshwater and execute photosynthesis, a process used by these organisms to convert sunlight into biochemical products such as chlorophyll, lipids and further ingredients. Scientists estimate that more than 400,000 different species of microalgae exist on our planet. However, only 25,000 species have been identified, a mere 15 of which are in current commercial use.

Microalgae have a unique natural defence mechanism – when encountering harsh environmental conditions, they can change the chlorophyll and lipids in their cell and form agents, which allow them to survive the “stressful” environment. During such a “stress phase” microalgae can create incredible natural agents with remarkable characteristics that can be very valuable. Much research is still to be done in order to discover the unique capabilities of most microalgae.

Growth & Stress Factors

There are two major aspects that are essential to the commercial cultivation of microalgae – creating the optimal conditions for growth and inducing the microalgae later to convert most of chlorophyll and lipids into natural agents. Scientific research has revealed the best conditions under which microalgae can grow, and in their combined capacity, these factors make the process of growing microalgae commercially both complicated and extremely delicate.

Growth Factors

Optimal growth conditions are affected by several factors, including:

- Light frequency

- Light intensity

- Suspension temperature

- pH-value

- Fertilizers

- Trace elements

- CO2 supply

- O2 release

- Shearing forces in the photobioreactor system

Stress Factors

In order to induce microalgae to convert chlorophyll and lipids into their incredible natural chemical agents, they have to be put through a “stress phase”. This is done through:

- Increase of temperature

- Increase of sunlight

- Increase of UV radiation

- Starvation of nitrate and other fertilizers

- Slight increase of suspension salinity

Marigan Microalgae

Creating the perfect conditions to cultivate microalgae has not even been possible in small-scale laboratory setups up to date. Our engineers have managed to invent unique processes and equipment to accomplish optimum conditions both for both laboratory setups and large scale commercial plants.

Through the revolutionary Marigan FFE Technology and Marigan FFE-X Technology we grow, optimize and transform microalgae under high-tech conditions, thereby delivering products of superior quantity and quality. Marigan cultivates microalgae in closed cycle, pressurized photobioreactor systems, using “modified” sunlight as a photo energy source and technical generated carbon dioxide as a carbon source; while nutrients, fertilizers and other ingredients are added in-time by computerized injection systems.

The growth and stress cycles in Marigan’s cultivation process are both controlled by a fully automated management system. Sensors built into the photobioreactors continuously measure the conditions of the suspension. Multiple disinfection systems of all raw materials including water and gases avoid risk of parasite infection, whereby automated detection systems and UVC treatment units ensure axenic strains of microalgae throughout the cultivation cycle.

Our harvesting and extraction processes use innovative methods to minimize degeneration of the valuable natural agents, which will at no point in the entire production process be in contact with oxygen, sunlight or excessive temperature, thereby maintaining maximum bio-activity, extraordinary purity and full anti-oxidative performance.

Marigan will produce prime quality microalgae of extraordinary purity and maximum bioactivity.

Importance of Prime Quality Microalgae

The availability of prime quality, natural microalgae in commercial volumes opens a whole new world of possibilities. Marigan’s natural chemical agents enable the pharmaceutical, nutraceutical and cosmetic industries to produce high quality products, develop new applications for microalgae, and introduce new products to the global market. Marigan’s prime quality microalgae will be used for the development of new generation medicines, enhanced cosmetics and more effective health supplements.

Products

Astaxanthin

Marigan’s astaxanthin will be delivered either as cell-ruptured biomass with an agent content of 4,8 – 5,1%, or as oleoresin with an agent content of 10% and embedded in a soluble oil of our customers’ choice.

Beta-Carotene

Marigan’s beta-carotene will be delivered as a cell-ruptured biomass, packed in sealed bags under vacuum with an agent content of 14 – 15%, or delivered as extracted powder with extraordinary purity.

Omega-3 EPA

The purest form of Omega-3 EPA is included in Marigan’s product portfolio, and is extracted from the microalgae Phaeodactilum tricornutum. Marigan’s Omega-3 acids are separated from the biomass and delivered as an oleoresin.

C-Phycocyanin

C-Phycocyanin is generated in a rich concentration from a new strain of cyano micro-organism and is an extremely valuable product.