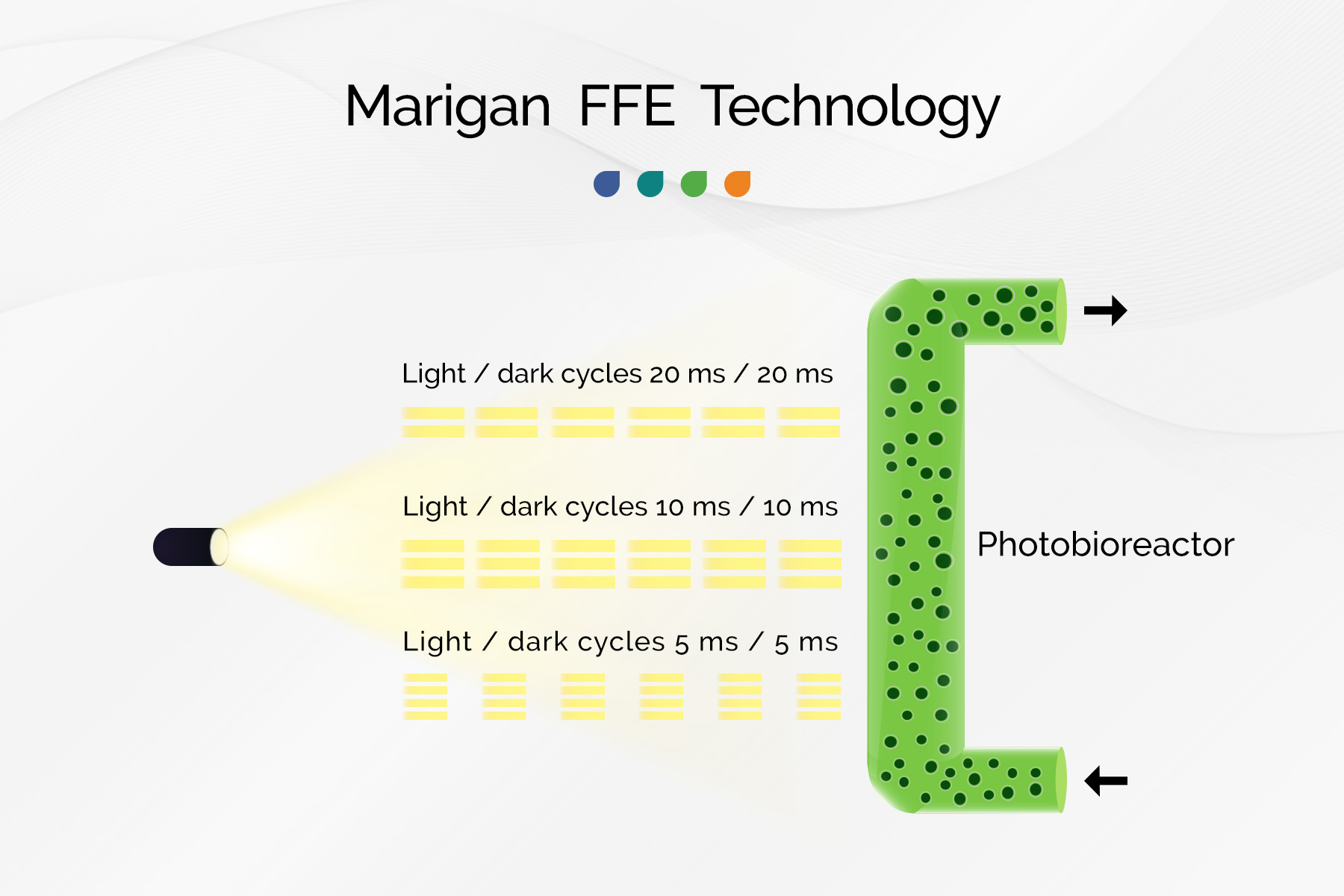

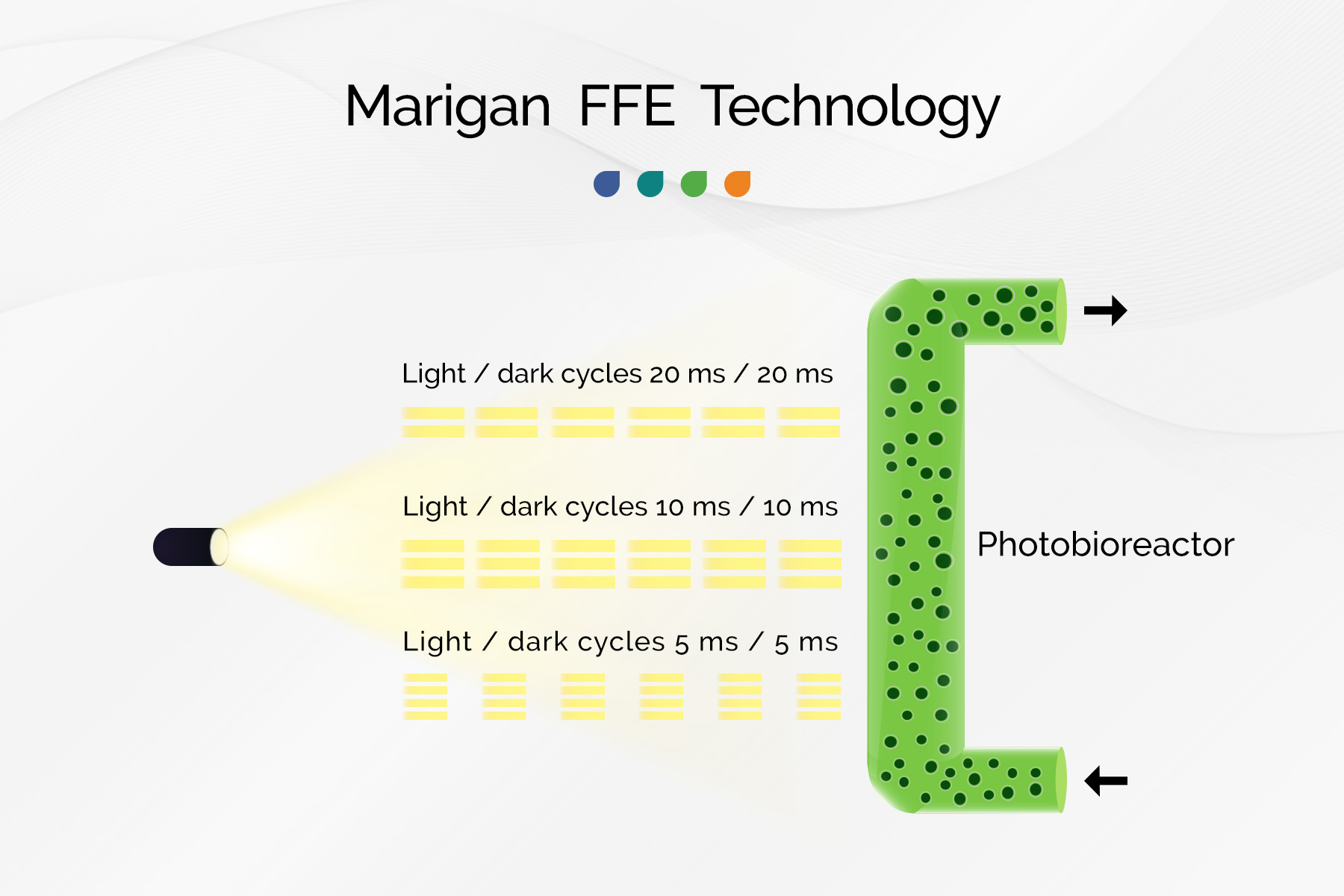

FFE Technology

The basic concept behind Marigan’s FFE Technology is the controlled distribution of sunlight through glasshouses to force a natural flashlight effect into photobioreactors, thereby creating optimal conditions to grow microalgae and to stimulate the production of the microalgae’s valuable natural agents.

FFE stands hereby for Forced Flashlight Effect. This term refers to scientific laboratory research that has proven that certain flashlight frequencies in combination with other optimizing conditions enhance the growth of microalgae by a factor of 4. Patents are pending.

Marigan’s cultivation process mimics optimum laboratory conditions, thereby enabling the production of prime quality microalgae in high volumes. Since laboratory equipment and conditions cannot be used in a large-scale production environment, Marigan’s scientists and engineers have invented an entirely new production process, and various new technologies and new equipment.

Process

Marigan cultivates microalgae using a Five Step process, split between the cultivation plant in Dubai, UAE and the extraction plant in Falkenstein, Germany.

In the cultivation plant in Dubai:

Cultivation

Growing microalgae at an optimized rate in FFE Photobioreactors, in appropriate glasshouses with electronically-controlled equipment. Then stressing the microalgae to induce the creation of the valuable natural agents.

Harvesting

Separating the biomass from the suspension and putting them through a washing process to remove any pollutants.

Drying

Drying of the biomass at mild temperature and under permanent Nitrogen cover, then vacuum packing for temperature-controlled transport to the extraction plant in Germany. Patents are pending.

In the extraction plant in Falkenstein:

Cell-Rupturing

Dry Cell-Rupturing of the biomass under permanent nitrogen cover. Patents are pending.

Extraction

Extracting the agents from the biomass by means of supercritical CO2 extraction process.

Quality Certification

In addition to being subject to an intensive internal quality testing, all Marigan products will undergo certification by a specialized external testing laboratory.

Quality Control

Every step in the entire production process is electronically controlled with an automated three-tier contamination management system that includes:

Prevention

The system continuously monitors the suspension, ensuring that optimal, contamination free conditions are maintained throughout.

Detection

The contamination management system will automatically detect any parasites that may occur during the production process, and subsequently trigger an automated contamination response.

Eradication

Once the system has detected contamination, it will identify the source and eliminate the contamination immediately by specific treatment.

Testing

In addition to the automated contamination management system, all Marigan’s products will be subject to internal quality testing.

Certification

Products that meet internal quality testing standards will also undergo independent certification by a specialized external testing laboratory